FDCS – Autonomous Technology

A Failure Determination & Compensation System – FDCS

Automotive Design evolution

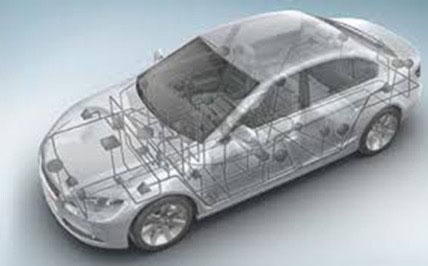

Vehicle are becoming increasingly complex, requiring sensorics to perform/monitor performance of the Vehicle. Additional system features, may increase risk, with potential impact on safety, vehicle performance and total cost

Sensors are a vital component within automotive electronic systems and are affecting the whole design process. Sensors are being deployed throughout the vehicle to meet evolving efficiency and security standards as well as address new environmental standards

According to a new report “Global Markets for Automotive Sensor Technologies demand for automotive sensors is booming. Analysts are predicting that the number of sensors could reach more than 100million by 2020. Currently, each vehicle has from 60 to 100 sensors on board and we can expect that number to rise as cars get ‘smarter’.”

Recent industry figures suggest the number of sensors is projected to reach as many as 200 per car based on current trends.

Go Sarvare, A FDCS Technology

Go Sarvare, A FDCS Technology, is a highly advanced “Active Predictive Analytics” solution integrated into the vehicle control systems. The technology actively monitors various vehicle systems and components, and through their performance/behavior, identifies system or sub system failures, impending failures, with time to failure information.

This information can be displayed to alert the driver of the failure and/or impending failure. Meanwhile switching to “soft” redundancy to compensate for the failed component, ensuring safe vehicle operating condition is fully maintained.

FDCS – Autonomous Technology: Background

The “Failure Detection and Compensation System (FDCS),” technology is a smart device that can be installed in vehicles of various levels of autonomy (primarily SAE levels 3, 4 and 5) and will greatly improve the safety of the vehicle.

Safety of a vehicle while operating under control of an interval ECU can be adversely affected by failure or by degraded performance of any component (or subsystem) of the system that directly affects system performance.

The compensation for a degraded performance component of an autonomous vehicle control system is best achieved by redundancy of the component or subsystem. However, this type of hardware redundancy is not practical in “land vehicles” from a cost perspective.

FDCS – Autonomous Technology: Solution

The technology, FDCS, clearly detects/identifies component/subsystem failures that are:

- ● Complete/catastrophic failures

- ● Intermittent failures

- ● Failures resulting from the gradual degradation in the performance of a component

- ● Capability of early detection of errors and gradual degradation in accuracy of the LIDAR/RADAR

As FDCS detects the level of component performance is outside of an allowable range, the compensation action is taken.

FDCS – Autonomous Technology: Explained

The FDCS provides what is termed “analytic redundancy”, this system incorporates analytical models of the vehicle dynamic response to each of the electronic control systems in autonomous vehicles.

In the case of a sensor degradation/failure, The FDCS is configured to replace the erroneous sensor output with accurate/correct value to sufficiently restore the control system performance to essentially normal, or at minimum, temporary vehicle safe operation.

With all necessary sensors in the FDCS, selected parameters are estimated accurately with a unique algorithm. Several experimental tests conducted on vehicles have resulted in estimates of known values for the parameters within approximately 0.1% of the correct/target value

In the case of a hardware component degradation/failure (e.g., an actuator), the component redundancy must be an actual replacement whenever this replacement is physically possible in the vehicle. However, the FDCS requires only dual redundancy since it can directly determine quantitatively the magnitude of the degradation.

FDCS – Autonomous Technology: Alert System

- ● The vehicle owner/manager (or driver if there is one) of the need for maintenance.

- ● In a level 5 autonomous vehicle, this information (or equivalent warning) can be sent through the appropriate vehicle external communication.

This information can be sent to a known person/office that manages the vehicle.

In some cases, the degradation of a component is sufficient such that the component can remain at an acceptable level of operation until the degradation reaches the tolerance limit for component performance. In this case, the FDCS can predict the “time to failure” which is when performance reaches the tolerance limit. This prediction is based on a extremely reliable statistical processing of the performance. The performance of system components can be represented quantitatively by the value of one or more parameters for the component model.

Engineering Services

Engineering Services